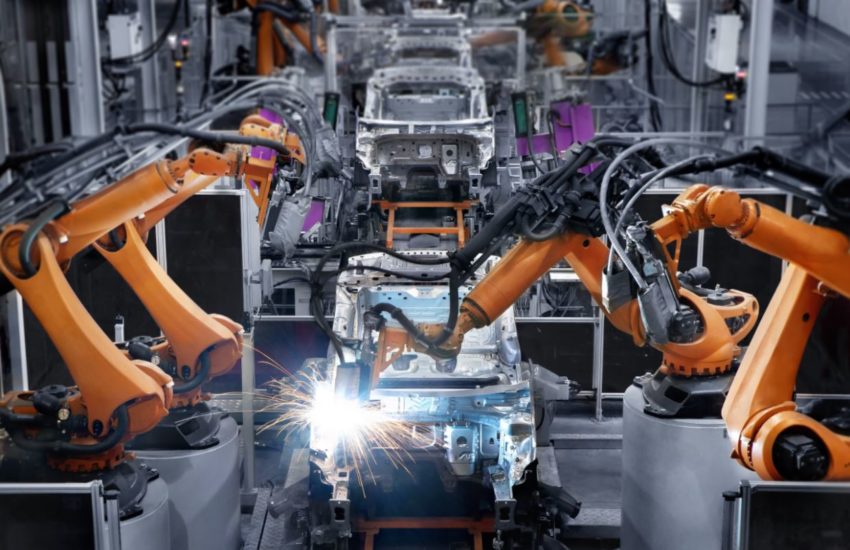

Advanced Manufacturing refers to the use of cutting-edge technologies such as automation, artificial intelligence (AI), and 3D printing to improve production efficiency, precision, and sustainability. This approach integrates smart manufacturing techniques to enhance product quality and reduce waste.

Industries utilizing advanced manufacturing employ robotics, Internet of Things (IoT), and digital twin simulations to optimize operations. These innovations enable real-time monitoring, predictive maintenance, and cost-effective production of complex parts.

Advanced manufacturing is transforming sectors such as aerospace, medical, automotive, and consumer electronics by allowing customization, reduced production cycles, and improved scalability. It is the future of industrial production, providing businesses with a competitive edge.

Key Features

- Utilizes AI, robotics, and smart automation for efficiency.

- Reduces production time and material waste.

- Enables on-demand manufacturing and mass customization.

Common Applications

- 3D printing of medical implants and aerospace components.

- Smart factories with IoT-based production monitoring.

- Custom automation solutions for high-precision industries.

Additive Manufacturing

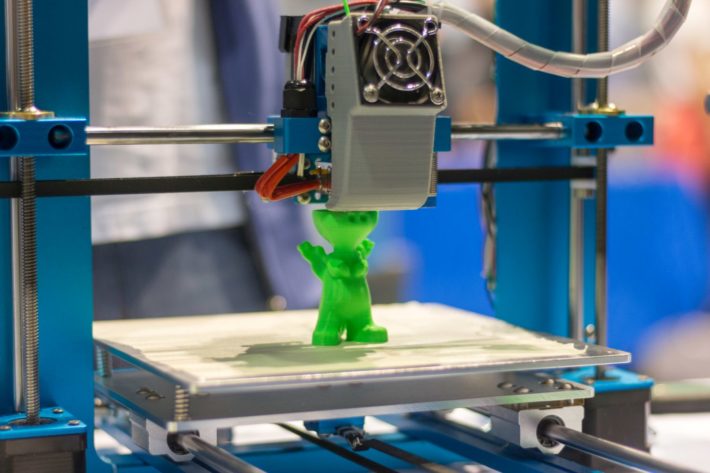

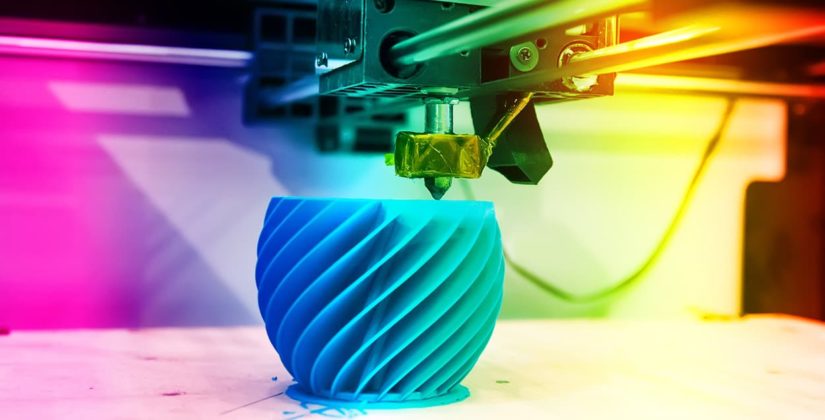

Additive manufacturing is the industrial production name for 3D printing, a computer controlled process to create 3D objects

3D Printing

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file

Rapid Prototyping

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using 3D computer

Sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by heat or pressure