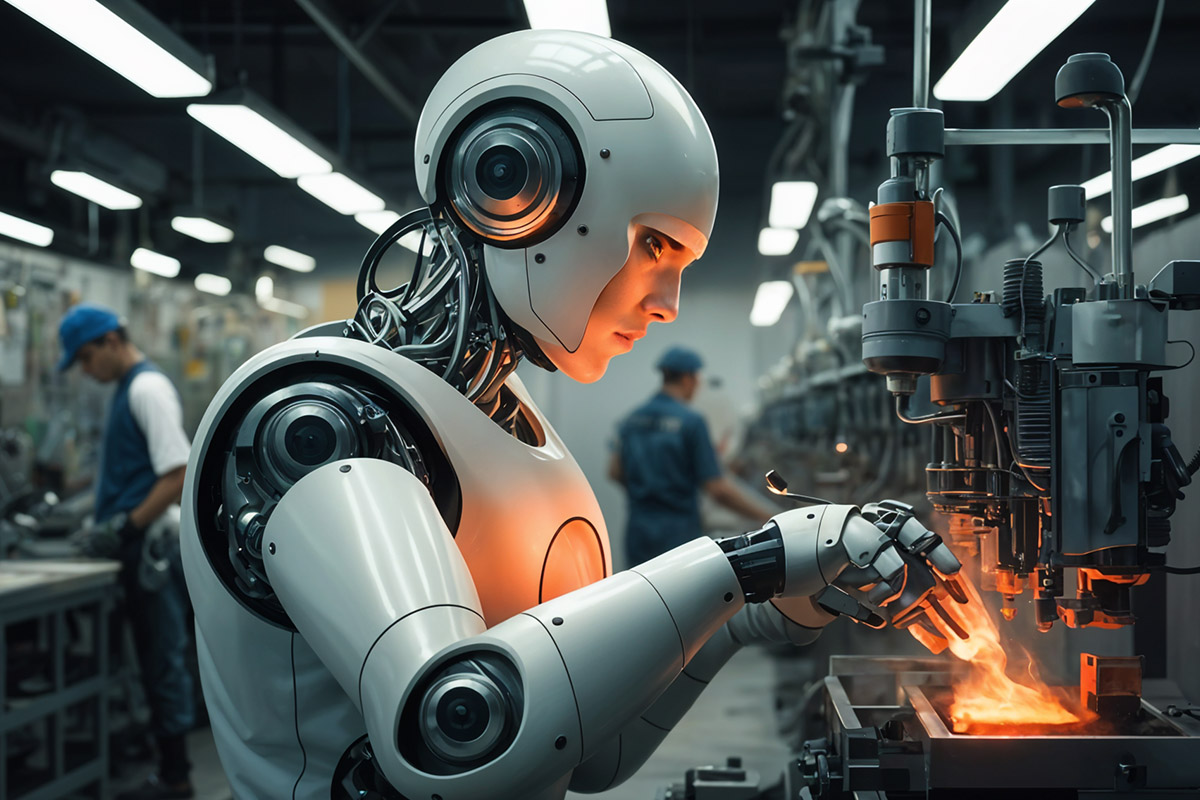

CNC Profile Cutting refers to a precise and automated process of cutting metal or other materials into specific shapes or profiles using a CNC (Computer Numerical Control) machine. This process involves the use of high-powered cutting tools, such as plasma, laser, or oxy-fuel, controlled by a computer that follows pre-programmed designs or CAD (Computer-Aided Design) files.

Key Features of CNC Profile Cutting

Precision

The CNC machine ensures highly accurate and consistent cuts as it follows the exact dimensions and patterns defined in the CAD file.

Versatility

It can handle various materials, including steel, aluminum, brass, and other alloys, as well as non-metals like plastic or wood.

Complexity

CNC profile cutting allows for intricate and complex designs that would be difficult to achieve with manual cutting.

Efficiency

The automation of the process significantly reduces material waste, time, and labor costs.

Common Applications

- Fabrication of components for industrial machinery.

- Creating custom parts for construction and engineering projects.

- Producing artistic or decorative designs in metalworking.

- Manufacturing of automotive, aerospace, and electronic parts.

Broching

Got questions or need assistance with your Industry needs?

Buffing

Polishing and buffing are finishing processes for smoothing a workpiece’s surface using an abrasive and a work wheel.

CNC & VMC Machining

It is a subtractive manufacturing process which typically employs computerized controls and machine tools.

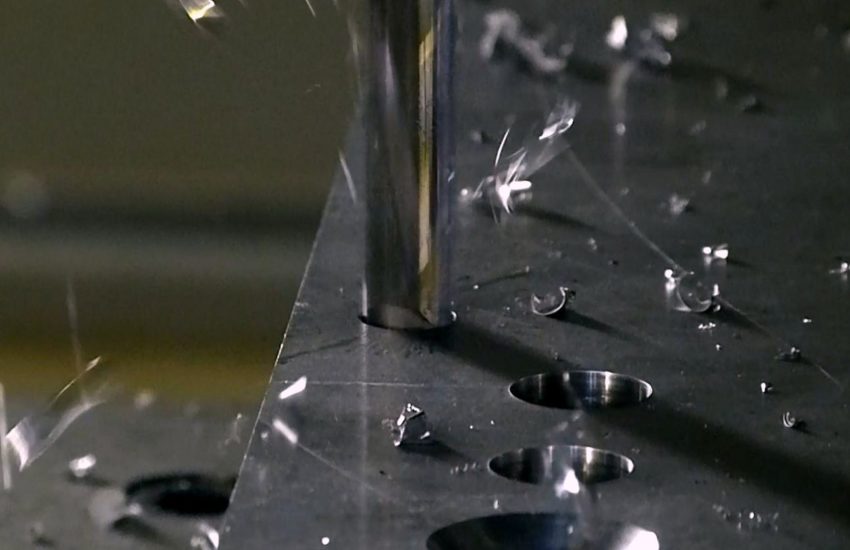

Drilling

For hard metals such as stainless steel, it’s best to use drill bits made of chrome vanadium, cobalt or titanium carbide.

Grinding

Metal Grinding is used to finish off rough edges, deburr metal parts, smooth welds, create sharp edges.

Groove Cutting

In manufacturing or mechanical engineering a groove is a long and narrow indentation built into a material

Hobbing

Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets on a hobbing machine Read More

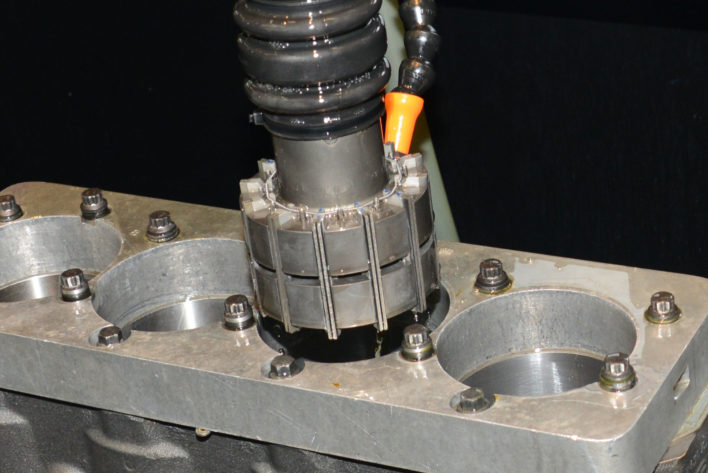

Honing

It is a process that produces a precision surface on a metal workpiece by scrubbing an abrasive stone against it.

Lapping

It is a controlled polishing process between two surfaces that are rubbed together to create an accurate finish on a part. Read More

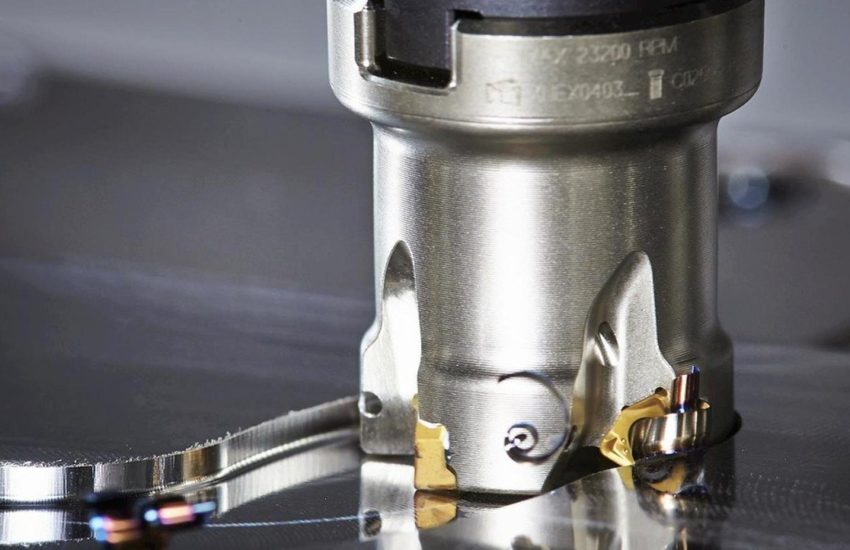

Milling

Milling is a cutting process that uses a milling cutter to remove material from the surface of a workpiece Read More

Reaming

Precision reamers are designed to enlarge the size of a previously formed hole by a small amount with high degree of accuracy

Shaping/ Forming

It is the metalworking process of fashioning metal parts and objects through mechanical deformation

Tapping

The process of cutting or forming threads using a tap is called tapping, whereas the process using a die is called threading.

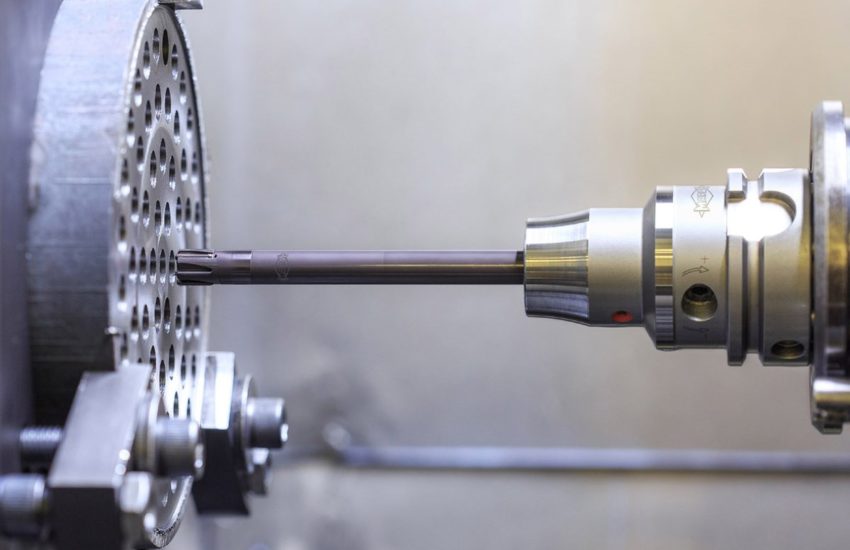

Turning

Turning is used to reduce the diameter of the work piece, usually to a specified dimension, and to produce a smooth finish. Read More