CNC Profile Cutting is an advanced fabrication process that utilizes CNC-controlled plasma, laser, or oxy-fuel cutting technology to create precise and complex shapes from various materials. This process ensures high accuracy, minimal material wastage, and a clean cutting finish, making it an essential method for industries requiring detailed metal fabrication.

One of the key benefits of CNC profile cutting is its ability to handle various thicknesses and materials with exceptional precision. Unlike traditional cutting techniques, CNC-controlled cutting follows digital CAD designs, ensuring consistent results across multiple batches. The automation involved also reduces production time and labor costs, making it a cost-effective solution for large-scale manufacturing.

CNC profile cutting is commonly used in industries such as construction, automotive, and industrial machinery manufacturing, where high-quality metal components are required. The ability to create intricate designs and complex patterns makes it a preferred choice for architectural and decorative applications as well.

Key Features of CNC Profile Cutting

Precision

The CNC machine ensures highly accurate and consistent cuts as it follows the exact dimensions and patterns defined in the CAD file.

Versatility

It can handle various materials, including steel, aluminum, brass, and other alloys, as well as non-metals like plastic or wood.

Complexity

CNC profile cutting allows for intricate and complex designs that would be difficult to achieve with manual cutting.

Efficiency

The automation of the process significantly reduces material waste, time, and labor costs.

Common Applications

- Fabrication of components for industrial machinery.

- Creating custom parts for construction and engineering projects.

- Producing artistic or decorative designs in metalworking.

- Manufacturing of automotive, aerospace, and electronic parts.

Profile Cutting

CNC Plasma/Gas Profile Cutting Machine — Miniature Based Machine. The machine cuts all shapes and parts as designed

Gas Cutting

A CNC profile cutter is a metal plate cutting machine that utilises plasma and or oxy-fuel cutting technology to cut through metal

Cutting On Band Saw Of Bars & Pipes

Band saw cutting is a fully automatic process and the most common method for cutting rod, bar, pipe, and tubing.

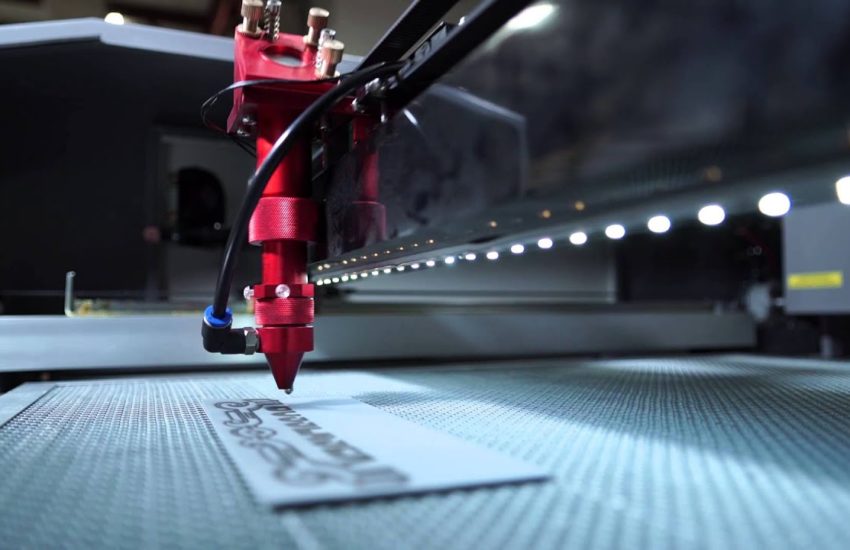

Laser Engraving

Laser engraving, which is a subset of laser marking, is the practice of using lasers to engrave an object.

Laser Jet Cutting

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications.

Machining: Wire Cut (EDM) Cutting

Wire electrical discharge machining is a high-precision method for cutting nearly any electrically conductive material.

Manual Gas Cutting Of Plates

The common methods used in cutting metal are oxygas flame cutting, air carbon-arc cutting, and plasma-arc cutting.