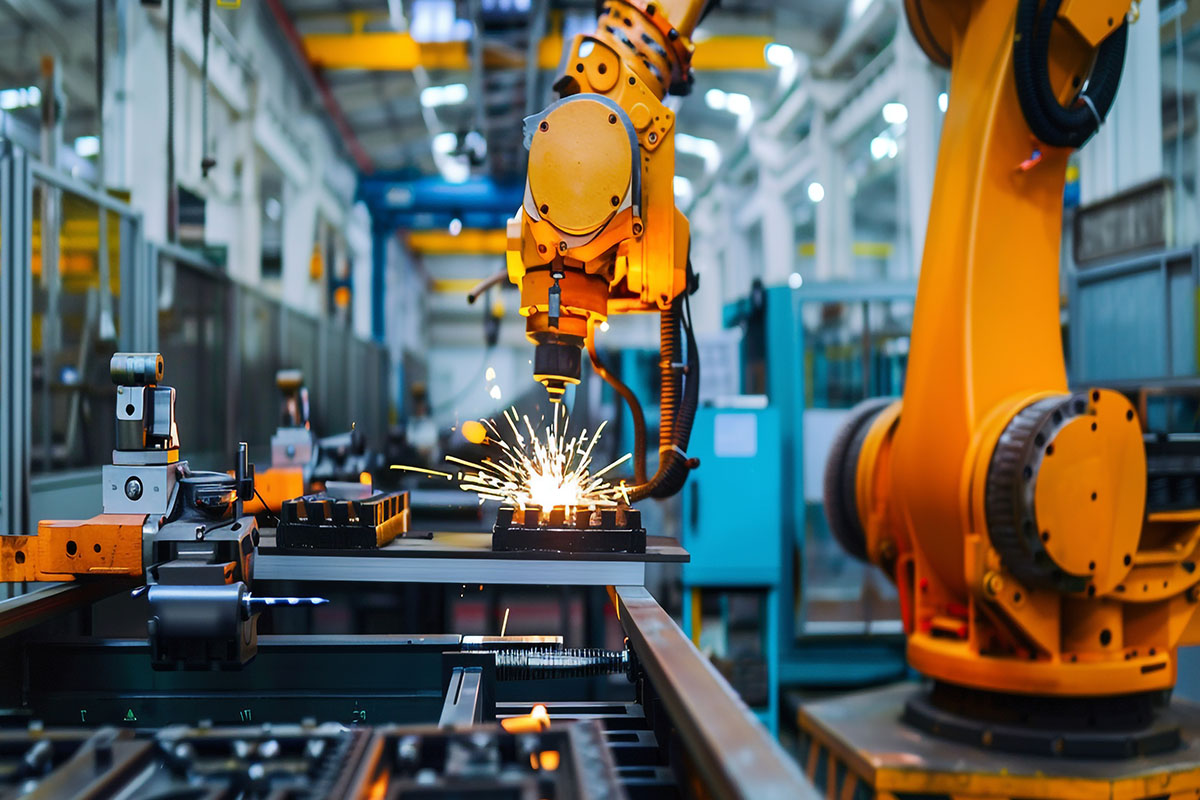

Welding and joining are essential fabrication processes used to fuse materials, primarily metals, through the application of heat, pressure, or both. These processes provide strong, durable connections that are vital in industries requiring high-strength components.

There are several welding techniques, including MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, arc welding, and resistance welding. Each method is selected based on the material type, thickness, and strength requirements. Some modern techniques, such as ultrasonic and friction welding, allow for the joining of dissimilar materials without excessive heat, further expanding their application.

Welding and joining are widely used in construction, shipbuilding, automotive, and aerospace industries. Advances in robotic and automated welding systems have improved precision, efficiency, and consistency, making welding a critical technology for large-scale industrial applications.

Key Features

- Provides strong and permanent material bonds.

- Various welding techniques for different applications.

- Automated welding improves consistency and efficiency.

Common Applications

- Construction and infrastructure projects.

- Manufacturing of machinery and industrial tools.

- Automotive and shipbuilding industries.

Arc Welding

Got questions or need assistance with your Industry needs?

Brazing

Got questions or need assistance with your Industry needs?

CO2 Welding

Got questions or need assistance with your Industry needs?

MIC/ TIG Welding

Got questions or need assistance with your Industry needs?

Press Fitting

Got questions or need assistance with your Industry needs?

Resistance Welding

Got questions or need assistance with your Industry needs?

Sintering

Got questions or need assistance with your Industry needs?

Soldering

Got questions or need assistance with your Industry needs?