Heat Treatment is a controlled process of heating and cooling metals to modify their mechanical properties. This process is essential for enhancing strength, hardness, toughness, and wear resistance, making materials more suitable for various industrial applications.

Different heat treatment techniques include annealing, quenching, tempering, and case hardening, each designed to achieve specific material characteristics. For example, annealing softens the metal for improved machinability, while quenching hardens the surface for increased durability. These processes ensure that components can withstand high stress, pressure, and temperature variations.

Heat treatment is crucial for industries such as aerospace, automotive, and tool manufacturing, where durability and reliability are paramount. With advancements in controlled heating technologies, manufacturers can achieve precise material modifications that enhance performance and longevity.

Carburizing

Carburization is a heat treatment process in which iron or steel absorbs carbon while the metal is heated

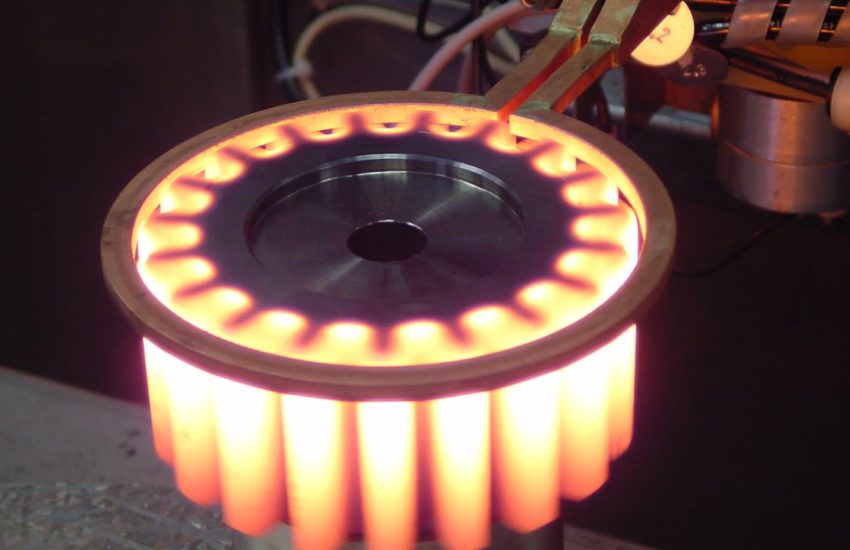

Flame Hardening

The result of flame hardening is a hard surface that is more resistant against wear and corrosion

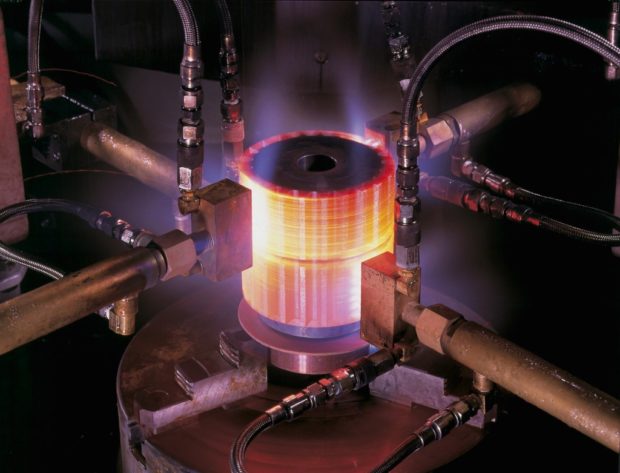

Induction Hardening

Induction hardening is a process used for the surface hardening of steel and other alloy components.